The Production Process of Mainstream High Temperature Resistant Fiber Casing/Heat Setting Tube

I. Introduction

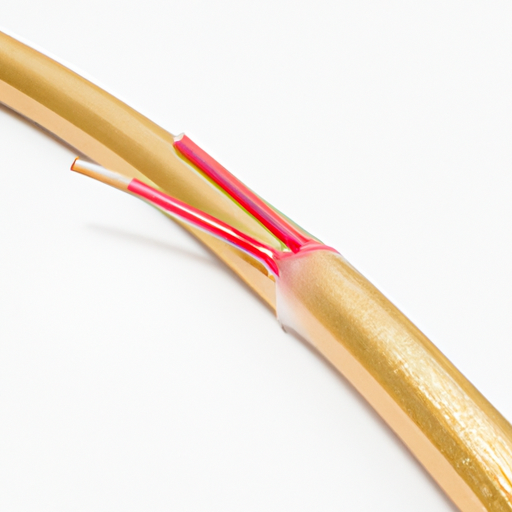

High temperature resistant fiber casings, also known as heat setting tubes, are specialized materials designed to withstand extreme thermal conditions. These tubes are essential in various industries, including aerospace, automotive, and electrical insulation, where they protect sensitive components from heat damage. The production process of these advanced materials involves several intricate steps, from selecting the right raw materials to the final quality assurance tests. This blog post will delve into the production process of mainstream high temperature resistant fiber casings, highlighting the significance of each stage.

II. Raw Materials

The foundation of any high temperature resistant fiber casing lies in its raw materials. The most commonly used fibers include aramid fibers (such as Kevlar), PBI (Polybenzimidazole), glass fibers, and carbon fibers. Each of these materials possesses unique properties that contribute to the overall performance of the final product.

A. Types of Fibers Used

1. **Aramid Fibers**: Known for their exceptional strength and thermal stability, aramid fibers are widely used in applications requiring high resistance to heat and abrasion.

2. **PBI**: This fiber is renowned for its outstanding thermal and chemical resistance, making it ideal for extreme environments.

3. **Glass Fibers**: These fibers offer excellent thermal insulation and are often used in applications where lightweight materials are essential.

4. **Carbon Fibers**: Known for their high tensile strength and low thermal expansion, carbon fibers are increasingly being utilized in high-performance applications.

B. Properties of Raw Materials

The raw materials selected for high temperature resistant fiber casings must exhibit several critical properties:

1. **Thermal Stability**: The ability to maintain structural integrity at elevated temperatures is paramount.

2. **Mechanical Strength**: High tensile strength ensures that the fibers can withstand physical stresses without breaking.

3. **Chemical Resistance**: Resistance to various chemicals is essential, especially in industrial applications where exposure to harsh substances is common.

C. Sourcing and Quality Control of Raw Materials

Sourcing high-quality raw materials is crucial for the production of reliable fiber casings. Manufacturers often establish relationships with trusted suppliers and implement stringent quality control measures to ensure that the fibers meet industry standards.

III. Fiber Preparation

Once the raw materials are sourced, the next step is fiber preparation, which involves selecting and blending the fibers to achieve optimal performance.

A. Fiber Selection and Blending

1. **Importance of Fiber Characteristics**: The specific characteristics of each fiber, such as strength and thermal resistance, play a significant role in the final product's performance.

2. **Blending Techniques for Optimal Performance**: Manufacturers may blend different types of fibers to enhance specific properties, such as combining aramid and glass fibers for improved thermal stability and mechanical strength.

B. Pre-treatment Processes

Before spinning, the fibers undergo pre-treatment processes, including:

1. **Cleaning and Drying**: Removing impurities and moisture ensures that the fibers are ready for the spinning process.

2. **Chemical Treatments**: In some cases, fibers may undergo chemical treatments to enhance their properties, such as increasing flame resistance.

IV. Spinning Process

The spinning process is where the prepared fibers are transformed into usable forms, such as yarns or filaments.

A. Overview of Spinning Techniques

1. **Wet Spinning**: This technique involves dissolving the polymer in a solvent and extruding it through a spinneret into a coagulation bath, where the fibers solidify.

2. **Dry Spinning**: In this method, the polymer is dissolved in a volatile solvent, and the solution is extruded into warm air, causing the solvent to evaporate and the fibers to form.

3. **Melt Spinning**: This process involves melting the polymer and extruding it through a spinneret, where it cools and solidifies into fibers.

B. Equipment Used in Spinning

1. **Spinning Machines**: These machines are designed to handle the specific requirements of each spinning technique, ensuring consistent fiber production.

2. **Spinning Nozzles**: The design of the nozzles affects the diameter and uniformity of the fibers produced.

C. Quality Control During Spinning

Quality control is critical during the spinning process. Manufacturers monitor fiber diameter and assess tensile strength to ensure that the fibers meet the required specifications.

V. Weaving or Knitting

After spinning, the fibers are woven or knitted to create fabric, which forms the basis of the heat setting tube.

A. Techniques for Creating Fabric

1. **Weaving**: This traditional method involves interlacing fibers at right angles to create a stable fabric structure.

2. **Knitting**: In contrast, knitting involves interlocking loops of yarn, resulting in a more flexible fabric.

B. Types of Fabrics Produced

1. **Woven Fabrics**: These fabrics are known for their strength and durability, making them suitable for high-stress applications.

2. **Non-woven Fabrics**: These fabrics are created by bonding fibers together, often resulting in lighter and more flexible materials.

C. Importance of Fabric Structure in Heat Resistance

The structure of the fabric plays a crucial role in its heat resistance. A well-designed fabric can provide better insulation and protection against high temperatures.

VI. Heat Setting Process

The heat setting process is a critical step that enhances the performance of the fiber casing.

A. Definition and Purpose of Heat Setting

Heat setting involves applying heat to the fabric to stabilize its dimensions and improve its thermal resistance. This process helps to lock in the desired properties of the fibers.

B. Equipment Used in Heat Setting

1. **Heat Setting Ovens**: These specialized ovens provide controlled heating to ensure uniform temperature distribution.

2. **Temperature and Pressure Controls**: Precise control of temperature and pressure is essential to achieve the desired results without damaging the fibers.

C. Parameters Affecting Heat Setting

1. **Temperature**: The heat setting temperature must be carefully controlled to avoid damaging the fibers.

2. **Duration**: The length of time the fabric is exposed to heat affects its final properties.

3. **Pressure**: Applying pressure during heat setting can enhance the dimensional stability of the fabric.

D. Effects of Heat Setting on Fiber Properties

1. **Dimensional Stability**: Heat setting helps to prevent shrinkage and distortion of the fabric during use.

2. **Enhanced Thermal Resistance**: The process improves the fabric's ability to withstand high temperatures, making it more suitable for demanding applications.

VII. Finishing Treatments

After heat setting, the fabric may undergo various finishing treatments to enhance its performance.

A. Types of Finishing Treatments

1. **Coating for Additional Protection**: Applying a protective coating can improve the fabric's resistance to abrasion and chemicals.

2. **Impregnation with Fire Retardants**: This treatment enhances the fabric's flame resistance, making it safer for use in high-risk environments.

B. Importance of Finishing in Enhancing Performance

Finishing treatments are crucial for maximizing the performance of high temperature resistant fiber casings. They can significantly improve the fabric's durability and safety.

C. Quality Control Measures Post-Finishing

Quality control measures are implemented after finishing to ensure that the treated fabrics meet the required standards for performance and safety.

VIII. Quality Assurance and Testing

Quality assurance is a vital aspect of the production process, ensuring that the final product meets industry standards.

A. Standards and Certifications for High Temperature Resistant Fibers

Manufacturers must adhere to specific standards and certifications to ensure the safety and reliability of their products.

B. Testing Methods

1. **Thermal Resistance Tests**: These tests assess the fabric's ability to withstand high temperatures without degrading.

2. **Mechanical Strength Tests**: Evaluating the tensile strength and durability of the fabric is essential for ensuring its performance in demanding applications.

3. **Chemical Resistance Tests**: Testing the fabric's resistance to various chemicals is crucial for applications in harsh environments.

C. Importance of Quality Assurance in Production

Implementing rigorous quality assurance measures helps manufacturers maintain high standards and build trust with their customers.

IX. Applications of High Temperature Resistant Fiber Casing/Heat Setting Tube

High temperature resistant fiber casings have a wide range of applications across various industries.

A. Industrial Applications

1. **Aerospace**: These materials are used in aircraft components to protect against extreme heat and ensure safety.

2. **Automotive**: High temperature resistant fibers are utilized in engine components and exhaust systems to withstand high thermal loads.

3. **Electrical Insulation**: These materials provide essential insulation for electrical components exposed to high temperatures.

B. Consumer Applications

1. **Protective Clothing**: High temperature resistant fibers are used in protective gear for firefighters and industrial workers.

2. **Home Insulation**: These materials are also employed in home insulation products to enhance energy efficiency and safety.

C. Future Trends and Innovations in Applications

As technology advances, the applications of high temperature resistant fiber casings are expected to expand, with innovations leading to even more efficient and effective materials.

X. Conclusion

The production process of high temperature resistant fiber casings and heat setting tubes is a complex and multifaceted endeavor. From selecting the right raw materials to implementing rigorous quality assurance measures, each step plays a crucial role in ensuring the final product's performance and reliability. As industries continue to evolve, the importance of these advanced materials will only grow, paving the way for future innovations and applications.

XI. References

- Academic journals on materials science and engineering.

- Industry reports on high temperature resistant fibers.

- Manufacturer specifications and guidelines for production processes.

This comprehensive overview of the production process highlights the significance of high temperature resistant fiber casings in modern applications, underscoring their vital role in ensuring safety and performance across various industries.